Contact us for more today!

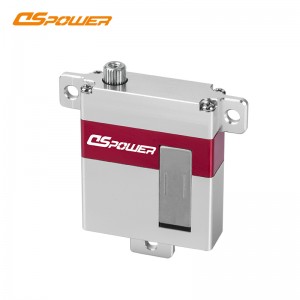

Anti-Shake Closed-Loop Servo Motor S009C

Product Info

| Brands | DSpower |

| Product Model | DS-S009C |

| Size | 23*12*26.5mm |

| Case Material | Aluminium alloy |

| Gear Type | Metal |

| Motor Type |

Coreless

|

|

Operating Voltage

|

6-7.4 V DC

|

| Standby Current |

≤ 40mA

|

|

Pulse Width Range

|

0-4096

|

| No Load Speed |

6V ≤ 0.15Sec/60°

7.4V ≤ 0.12Sec/60°

|

|

Operating Torque

|

6V ≥ 4.5 Kgf.cm

7.4V ≥ 5Kgf.cm

|

| Stall Current |

6V ≤ 2.5 A

7.4V ≤ 3 A

|

| Stall Torque(static) |

6V ≥ 10 Kgf.cm

7.4V ≥11Kgf.cm

|

| Operating Travel Angle |

360°±10°(0-4096)

|

| Mechanical Limit Angle |

360

|

| Servic Support | OEM/ODM |

Need Custom Specifications?

We have a R&D team of more than 40+ people to support your project!

Product Profile

Engineered for space-constrained automation, the S009C redefines precision in compact actuation. With a 26.5mm aluminum alloy body and closed-loop feedback control, this servo delivers 40kgf·cm torque while eliminating vibration in applications ranging from robotic finger joints to espresso machine valve control.

Key Industry-Specific Advantages:

✅ Ultra-Precise Positioning:Virtual position technology achieves ±0.5° repeatability for 3D printer belt drives.

✅ Silent Operation:Low-noise design (≤25dB) ideal for coffee machine grinders and office automation.

✅ Thermal Management:Integrated aluminum heat dissipation ensures 24/7 operation in 60°C environments.

✅ Anti-Shock Durability:Withstands 50G impact forces for drone gimbal stabilization and industrial claw gripping.

Critical Applications:

- Robotics:Biomimetic hand joint articulation

- Drones:FPV camera gimbal micro-adjustment

- 3D Printing:Extruder filament feed control

- Coffee Machines:Precision pressure valve actuation

- Industrial Automation:SCARA robot end-effector control

Highlights of Our Servos

Self-developed protection system of mechanical transmission and electric drive to utilize the best function of the servo.

Want More Technical Details?

Product Certification

Passed FCC, CE, ROHS, REACH, EMC product certification and more than 100+ patents.

Our Service Process

FAQs

A: Yes, Through 10+years research and development of servo, De Sheng technical team is professional and experienced to offer customized solution for OEM,ODM customer, which is one of our most competitive advantage.

If above online servos does not match your requirements, please do not hesitate to send message to us, we have hundreds of servos for optional, or customizing servos based on demands, it is our advantage!

Sample order is acceptable for testing your market and checking our quality And we have strict quality control systems from raw material incoming until finished product delivery out.

Normally, 10~50 business days, it depends on requirements, just some modification on standard servo or a totally new design item.

Order less than 5000pcs, it will take 3-15 business days.

The Application of DSpower Servo Solution

Our servos can be customized to meet customer needs and are used in STEAM education, robots, model airplanes, unmanned aerial vehicles, intelligent smart home control, automation equipment, micro-mechanical control transmission and other fields.

Found a Servo for Your Project?

About DSpower

DSpower was founded in May, 2013. The main R & D production and sales of servos, micro-servos, etc. We have more than 500+ employees, including more than 40+ R&D personnel, more than 30 quality inspection personnel, with more than 100+ patents; IS0:9001 and IS0:14001 certified enterprises. The maximum daily production capacity is more than 50,000 pieces.

What Sets Our Factory Unique?

10+ years experience, self-developed protection system, automated production, professional customized support

Unique Quality Inspection Equipment.

We have advanced CMM testing equipments, exclusive developed clutch structure testing equipments, spectral analyzing instruments and other routine testing equipments to ensure that the quality of our products meets high quality standards.

More Than 40+ R&D Team Support Customization

We have an experienced R&D team of more than 40 members to provide full technical support from prototype customization to mass production of micro servos for our customers worldwide. After more than 10 years of development, our team has been awarded more than 100+ patents.

Automated Production

Our factory has more than 30 production lines, with many intelligent equipments such as Japan HAMAI CNC type automatic hobbing machine, Japan Brother SPEEDIO high-speed drilling and tapping CNC machining center, Japan imported NISSEI PN40, NEX50 and other high-precision injection molding machines, automatic shaft pressing machine, and center shaft into the shell machine. The daily output is up to 50,000 pieces and the shipment is stable.

International Certification & High Quality

Passed FCC, CE, ROHS, REACH, EMC product certification and more than 100+ patents.